rajnandini

New member

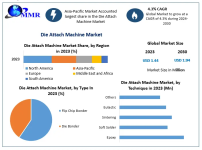

Die Attach Machine Market Projected to Reach USD 1.94 Million by 2030

Advancements in Semiconductor Packaging and Rising Consumer Electronics Demand Fuel Market Growth

The Die Attach Machine Market Trends valued at approximately USD 1.44 million in 2023, is anticipated to reach USD 1.94 million by 2030, exhibiting a Compound Annual Growth Rate (CAGR) of 4.3% during the forecast period. This growth is primarily driven by technological advancements in semiconductor packaging, increasing demand for consumer electronics, and the proliferation of electric vehicles.

Market Definition and Overview

Die attach machines, also known as die bonders or die mount machines, are integral to the semiconductor packaging process. These machines facilitate the precise attachment of silicon chips onto die pads or cavities using various bonding techniques such as epoxy, soft solder, sintering, and eutectic methods. The accuracy and reliability of die attach machines are crucial for ensuring optimal performance and longevity of semiconductor devices. They find extensive applications across industries, including radio frequency (RF) and Micro-Electro-Mechanical Systems (MEMS), optoelectronics, logic and memory devices, Complementary Metal-Oxide-Semiconductor (CMOS) image sensors, and Light Emitting Diodes (LEDs).

Market Growth Drivers and Opportunities

The die attached machine market is segmented based on type, technique, and application.

Country-Level Analysis

The die attached machine market is characterized by the presence of several key players focusing on innovation, strategic partnerships, and geographic expansion to strengthen their market position. Notable companies include:

Conclusion

The global die attached machine market is poised for steady growth, driven by advancements in semiconductor packaging technologies, increasing demand for consumer electronics, and the expansion of the electric vehicle market.

Connect With US

Advancements in Semiconductor Packaging and Rising Consumer Electronics Demand Fuel Market Growth

The Die Attach Machine Market Trends valued at approximately USD 1.44 million in 2023, is anticipated to reach USD 1.94 million by 2030, exhibiting a Compound Annual Growth Rate (CAGR) of 4.3% during the forecast period. This growth is primarily driven by technological advancements in semiconductor packaging, increasing demand for consumer electronics, and the proliferation of electric vehicles.

Market Definition and Overview

Die attach machines, also known as die bonders or die mount machines, are integral to the semiconductor packaging process. These machines facilitate the precise attachment of silicon chips onto die pads or cavities using various bonding techniques such as epoxy, soft solder, sintering, and eutectic methods. The accuracy and reliability of die attach machines are crucial for ensuring optimal performance and longevity of semiconductor devices. They find extensive applications across industries, including radio frequency (RF) and Micro-Electro-Mechanical Systems (MEMS), optoelectronics, logic and memory devices, Complementary Metal-Oxide-Semiconductor (CMOS) image sensors, and Light Emitting Diodes (LEDs).

Market Growth Drivers and Opportunities

- Surging Demand for Consumer Electronics: The global consumer electronics market is experiencing robust growth, leading to an increased need for advanced semiconductor components. Devices such as smartphones, wearables, and home appliances require compact and efficient semiconductors, thereby propelling the demand for die attach machines. The trend towards miniaturization and enhanced functionality in electronic devices further accentuates this demand.

- Advancements in Semiconductor Packaging Technologies: Innovations in semiconductor packaging, particularly the development of die-to-wafer (D2W) hybrid bonding platforms, are revolutionizing the industry. These platforms enable unprecedented 2.5D and 3D integration, allowing for enhanced device performance and reduced form factors. The anticipated market introduction of Chip-to-Wafer (C2W) hybrid bonding for stacked memory and logic devices between 2022 and 2023 is expected to significantly boost the die attach machine market.

- Expansion of the Electric Vehicle (EV) Market: The automotive industry's shift towards electric vehicles has led to a heightened demand for power semiconductors and advanced electronic components. Die attach machines play a pivotal role in the assembly of these components, ensuring reliability and efficiency. As EV adoption accelerates globally, the demand for die attach machines is projected to rise correspondingly.

- Growth in the Asia-Pacific Region : Countries like China and Taiwan are major hubs for electronics manufacturing, contributing significantly to the die attached machine market. The mass production of electronic products, including smartphones and wearable devices, in these countries drives the demand for die attached equipment. Additionally, increased investments in semiconductor sector development in nations such as India and China are expected to further stimulate market growth.

The die attached machine market is segmented based on type, technique, and application.

- By Type :

- Die Bonder : This segment dominates the market in 2023, accounting for over three-quarters of the total market share. Die bonders are essential for attaching semiconductor dies to substrates or packages, ensuring precise placement and strong adhesion. The segment is projected to grow at a CAGR of 3.5% during the forecast period.

- Flip Chip Bonder : Flip chip bonders are specialized machines used for attaching semiconductor devices with the active side facing down, enabling direct electrical connections. This segment is expected to witness the fastest growth, with a projected CAGR of 6.9% from 2024 to 2030, driven by the increasing adoption of flip chip technology in advanced packaging solutions.

- By Technique :

- Epoxy : Utilizes adhesive materials to bond the die to the substrate, offering flexibility and ease of use.

- Soft Solder : Involves the use of solder alloys with low melting points, providing strong mechanical bonds and good electrical conductivity.

- Sintering : Employs pressure and heat to bond materials without melting, resulting in high thermal and electrical conductivity.

- Eutectic : Utilizes a specific alloy composition that melts at a lower temperature, allowing for strong and reliable bonds.

- Others : Includes emerging techniques and hybrid methods tailored for specific applications.

- By Application :

- RF and MEMS : Die attach machines are crucial in the assembly of RF components and MEMS devices, which require precise placement and bonding to function correctly.

- Optoelectronics : Involves devices that source, detect, and control light, such as LEDs and photodiodes, where die attach machines ensure accurate alignment and bonding.

- Logic and Memory : Pertains to semiconductor devices used in processing and storage applications, where reliable die attachment is essential for performance.

- CMOS Image Sensors : Sensors that convert light into electronic signals, widely used in cameras and imaging devices, requiring precise die attachment for optimal image quality.

- LEDs : Light-emitting diodes used in various lighting applications, where die attached machines facilitate efficient assembly and performance.

- Others : Encompasses emerging applications in automotive, healthcare, and industrial sectors.

Country-Level Analysis

- United States : The US die attached machine market is experiencing growth due to significant investments in semiconductor manufacturing and research. The country's focus on maintaining technological leadership and self-sufficiency in semiconductor production has led to increased demand for advanced die attached equipment.

- Germany : As a leader in automotive manufacturing and industrial automation, Germany's market is driven by the need for advanced semiconductor components. The country's emphasis on Industry 4.0 and the transition towards electric vehicles contributes to the growing demand for die attached machines.

The die attached machine market is characterized by the presence of several key players focusing on innovation, strategic partnerships, and geographic expansion to strengthen their market position. Notable companies include:

- Kulicke & Soffa Industries, Inc. : A leading provider of semiconductor packaging and electronic assembly solutions, offering a range of die attached machines known for precision and reliability.

- ASM Pacific Technology Limited : Specializes in the manufacturing of equipment for the semiconductor and electronics industries, including advanced die attach solutions.

- Palomar Technologies : Offers high-precision die attach equipment and solutions, catering to various applications such as optoelectronics and RF devices.

- Besi (BE Semiconductor Industries NV) : Provides a comprehensive portfolio of die attached machines, focusing on high-performance and cost-effective solutions for semiconductor packaging.

- Shinkawa Ltd. : Engages in the development and production of semiconductor manufacturing equipment, including die bonders known for their accuracy and efficiency.

Conclusion

The global die attached machine market is poised for steady growth, driven by advancements in semiconductor packaging technologies, increasing demand for consumer electronics, and the expansion of the electric vehicle market.

Connect With US